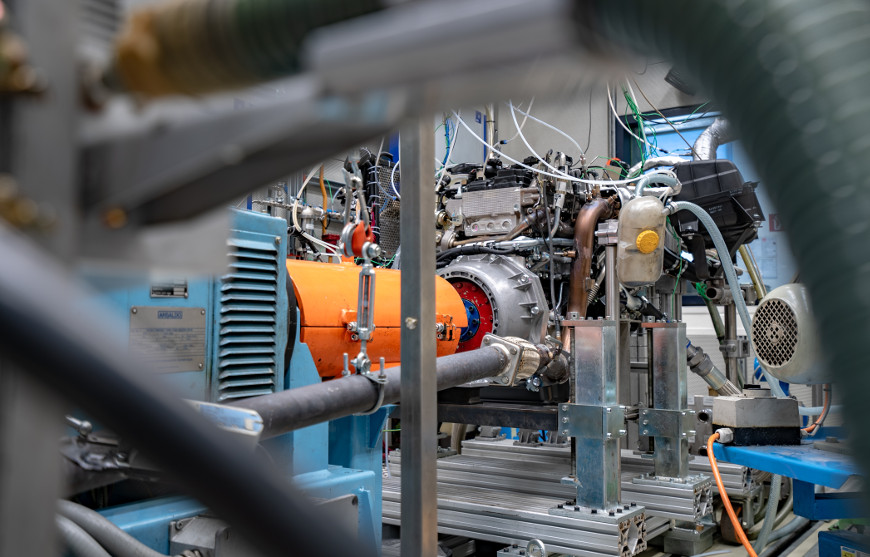

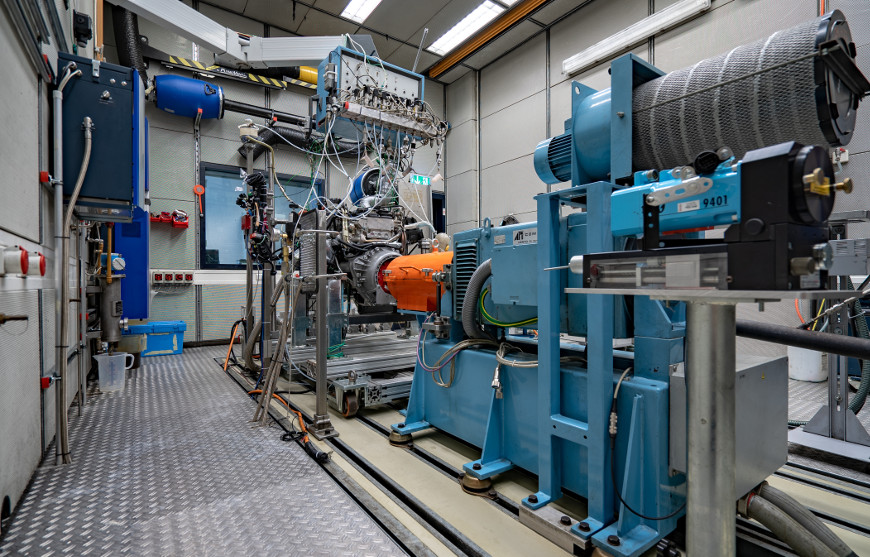

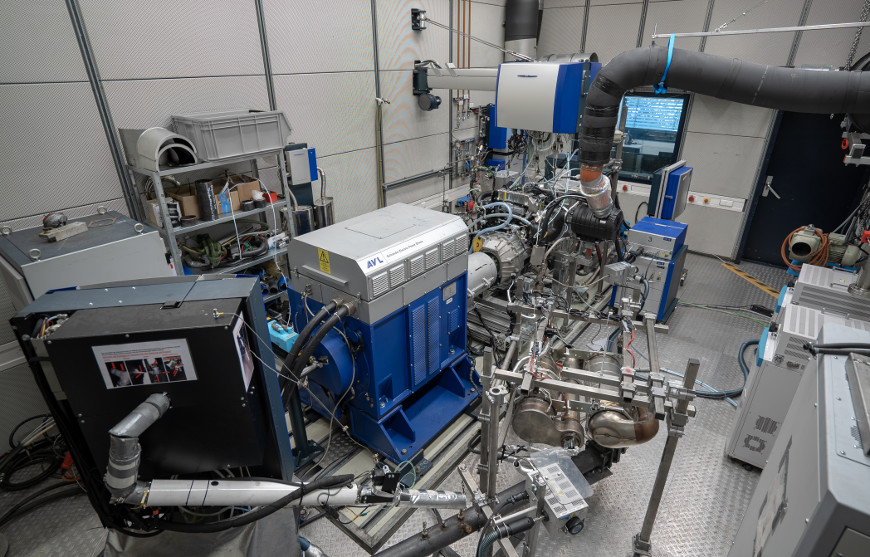

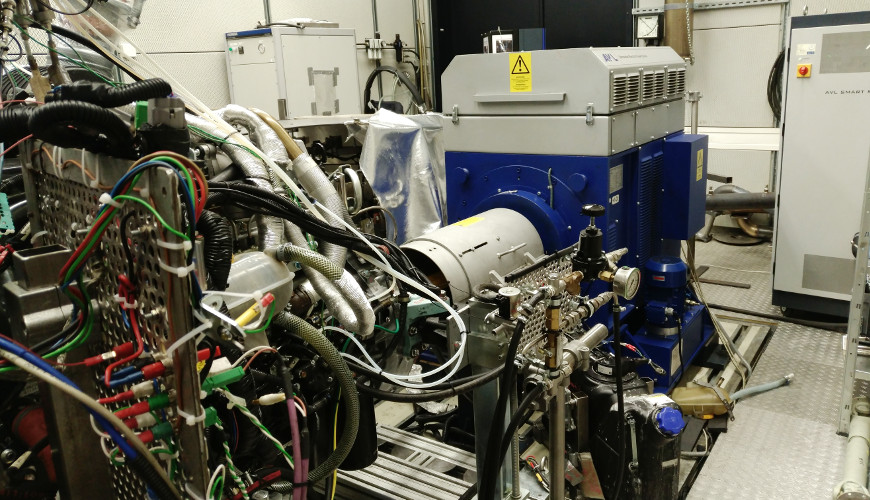

We run 8 performance test benches with capabilites from 500Nm up to 2000Nm for development purpose only. These test benches are certified for homologation tests to achieve certificates with and without attendance of legal authority. Certain test benches are able to perform RDE (Real Driving Emission) tests to support the development of WLTP and RDE which is part of current legislation for passenger cars and trucks. All required heavy duty tests (example: ECE-R49) and non road tests (example: ECE-R96) are implemented to cover regulations like Euro VI and above. State of the art exhaust gas and particulate measurement devices are used for these tests (FTIR, Particulate Counter, Dual Line exhaust gas analyzers, Smart Sampler, MDLT and so on). Our Engine and emission development is assisted by modern software tools like DoE, car-maker, truck-maker, virtual testbed etc.).

Another engine test bench is our friction performance test bench which becomes important as an elevating factor in engine development.

The engine testbenches are operated in actively guided two-shift operation mode and in addition (if required)with unguided but monitored night shift operation mode.